1

PRODUCTION FACTORY

40 Tons

MONTHLY PRODUCTION

20

INTERNATIONAL PROJECT

25

EMPLOYEE STAFF

Arena Metal Aluminum

Arena Metal, established in 2011 in İzmir, is a distinguished brand specializing in the high-pressure casting of light metals, operating within the automotive and metal aluminum sectors. With expertise in high-pressure aluminum injection casting, gravity casting, precision machining, mold design, and manufacturing, Arena Metal meticulously fulfills its operations through a team of skilled and experienced professionals. The company meets the needs of its customers with products such as automotive spare parts and industrial machinery spare parts. Furthermore, Arena Metal serves various sectors, including construction, lighting, and furniture.

Why Choose Us?

We place customer satisfaction at the core of our entire business process and take pleasure in our work within an efficient working environment. This enables us to meet customer expectations and add value to the companies we work with. By staying abreast of international sector developments and making technological investments, we provide advanced services to our customers in Turkey. This allows us to stand out from our competitors and continue our journey with confidence, supported by the recommendations of our satisfied customers.

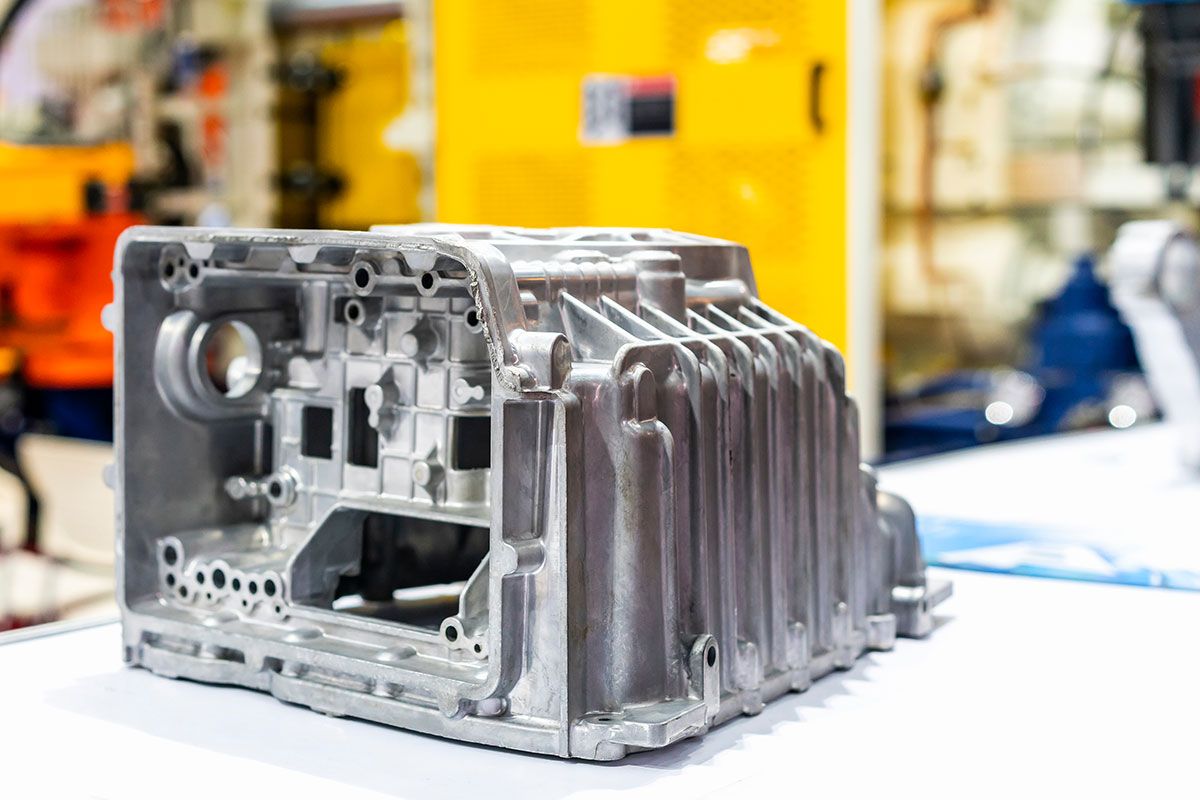

What We Do?

Arena Metal, established in 2011 in İzmir, is a prominent brand operating in the automotive and metal aluminum sectors, specializing in high-pressure casting of light metals. We meticulously carry out high-pressure aluminum injection casting, gravity casting, precision machining, mold design, and manufacturing, thanks to our team of skilled and experienced professionals.

Precision Machining

Precision machining is the manufacturing process of machine parts that have been designed on paper and pre-engineered. For our trusted customers, we ensure the production of these designed products by using appropriate tools and machinery. By employing tools and workpieces specifically used for production, we achieve the desired results through their relative movement to each other.

Kokil Casting

Kokil casting is the optimal solution for our customers seeking a broad product range. This method, which can incorporate various alloys, provides enhanced mechanical properties and improved machinability. The primary advantage of the kokil casting system is its suitability for mass production. Additionally, compared to standard sand casting, it offers greater strength, usability, and superior mechanical characteristics.

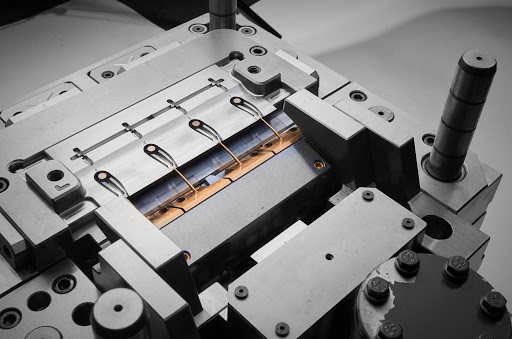

Mold Design and Production

The design and production of the desired mold is a process that must be handled with meticulous attention from start to finish. As a company, we operate with full awareness of the importance of this process. After agreeing with our customer on the fundamentals of the mold, we move on to the stage where the details of the mold are determined. By creating the mold through 3D modeling, we make it extra detailed and controllable.

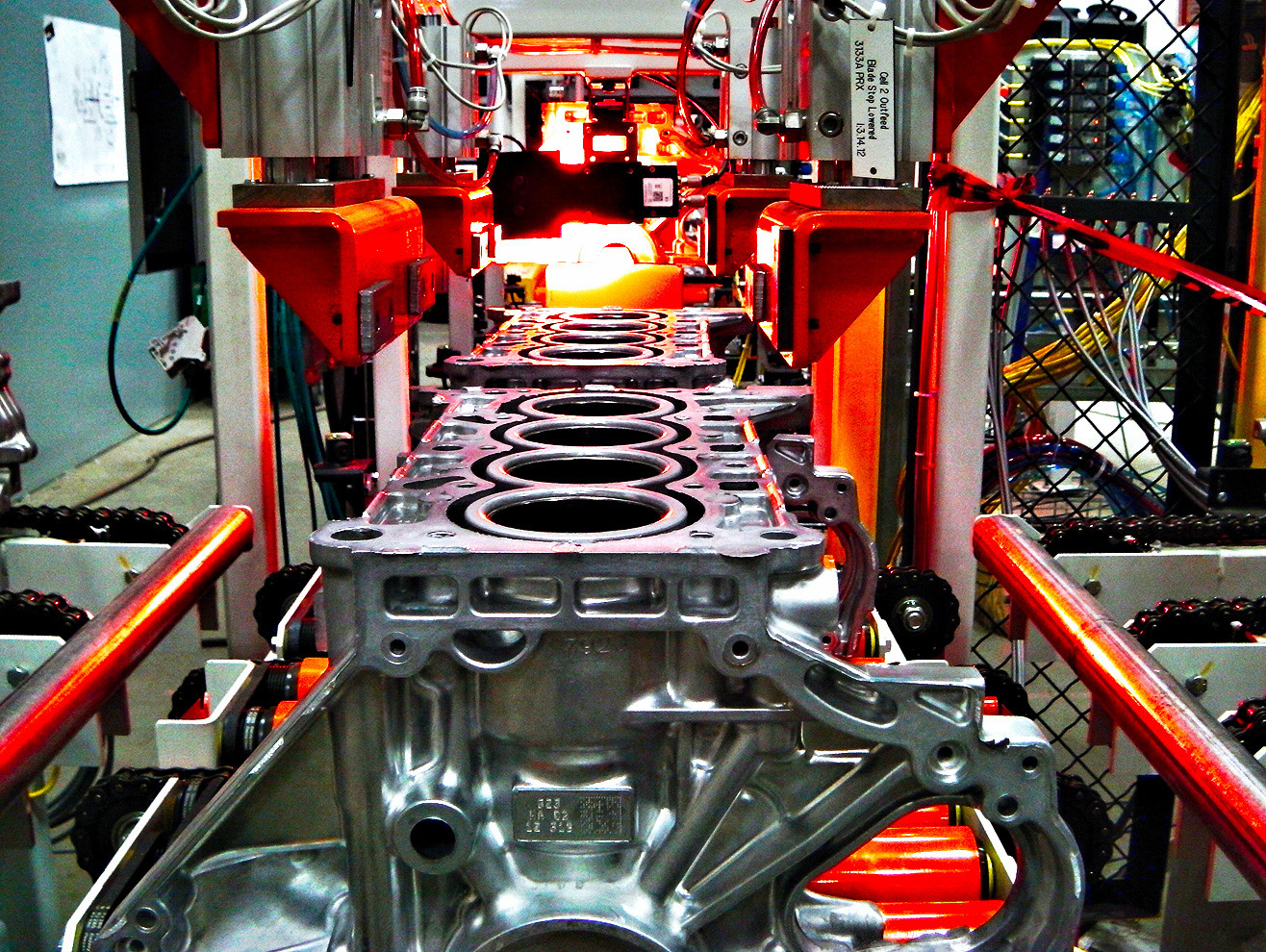

High-Pressure Aluminum Injection Casting

High-pressure aluminum injection casting is the process of filling metal molds with molten aluminum raw material using high pressure. The primary advantage of the high-pressure aluminum injection system is its ability to save a significant amount of time while enabling the production of complex-shaped parts.